The brand highlights its locally produced solutions and integrated electronics portfolio at AWE, Hotelex, China Refrigeration Exhibition and Chinashop

April 16, 2025. Embraco, a global provider of refrigeration technology for the residential and commercial cold chain and part of Nidec Global Appliance, is strengthening its presence in the Chinese and broader Asia-Pacific commercial refrigeration market by participating in four of the region’s most important trade shows: China Refrigeration Exhibition (CRH) (April 27–29), Chinashop (May 8–10), this one for the first time, Hotelex (March 30–April 2), and AWE 2025 (March 20–23), this one focused on home appliances. These events come at a special moment for the brand to celebrate its 30-year presence in the region and to showcase the breadth of its localized, sustainable, and integrated refrigeration solutions portfolio.

“Hotelex and AWE are trade shows that we have been participating for a few years now, and the inclusion of China Refrigeration and Chinashop in the agenda are an important step to strengthen our relationship with the commercial refrigeration market in the region, specially in a year in which we celebrate 30 years of Embraco presence in the country, and have a strong portfolio of compressors produced in China for this segment. The two events have strategic complementary targets: one focused on the industry and the other on the end user, respectively”, says Esequias Pereira Junior, Sales Director for the Commercial Appliances segment in the Asia Pacific region.

Together, the four trade shows represent a comprehensive cross-section of the appliance and refrigeration markets in Asia. China Refrigeration (CRH) brings together a highly technical audience of engineers, system designers, and decision-makers from the refrigeration, HVAC (heating, ventilation and air conditioning), frozen food and food processing chains. Chinashop, Asia’s leading retail trade fair, focuses on solutions for supermarkets and convenience stores, drawing retail executives and refrigeration engineers. Hotelex connects Embraco with the hospitality and food service market, gathering professionals from commercial kitchens, restaurants, and refrigeration equipment manufacturers. Finally, AWE, one of the world’s largest exhibitions for home appliances and consumer electronics, reinforces Embraco’s presence in the residential segment.

Electronics integration: the future of refrigeration

At Hotelex, China Refrigeration and Chinashop, all events focused on commercial refrigeration, Embraco is showcasing its recently launched Sync It All portfolio, a set of electronic devices that work in synchrony to optimize the performance of commercial refrigeration systems. It includes the Embraco Air fan, the Embraco Sync controller, and the YouControl interface (software), all working with Embraco variable-speed compressors — enabling faster setup, greater energy efficiency, and improved temperature stability.

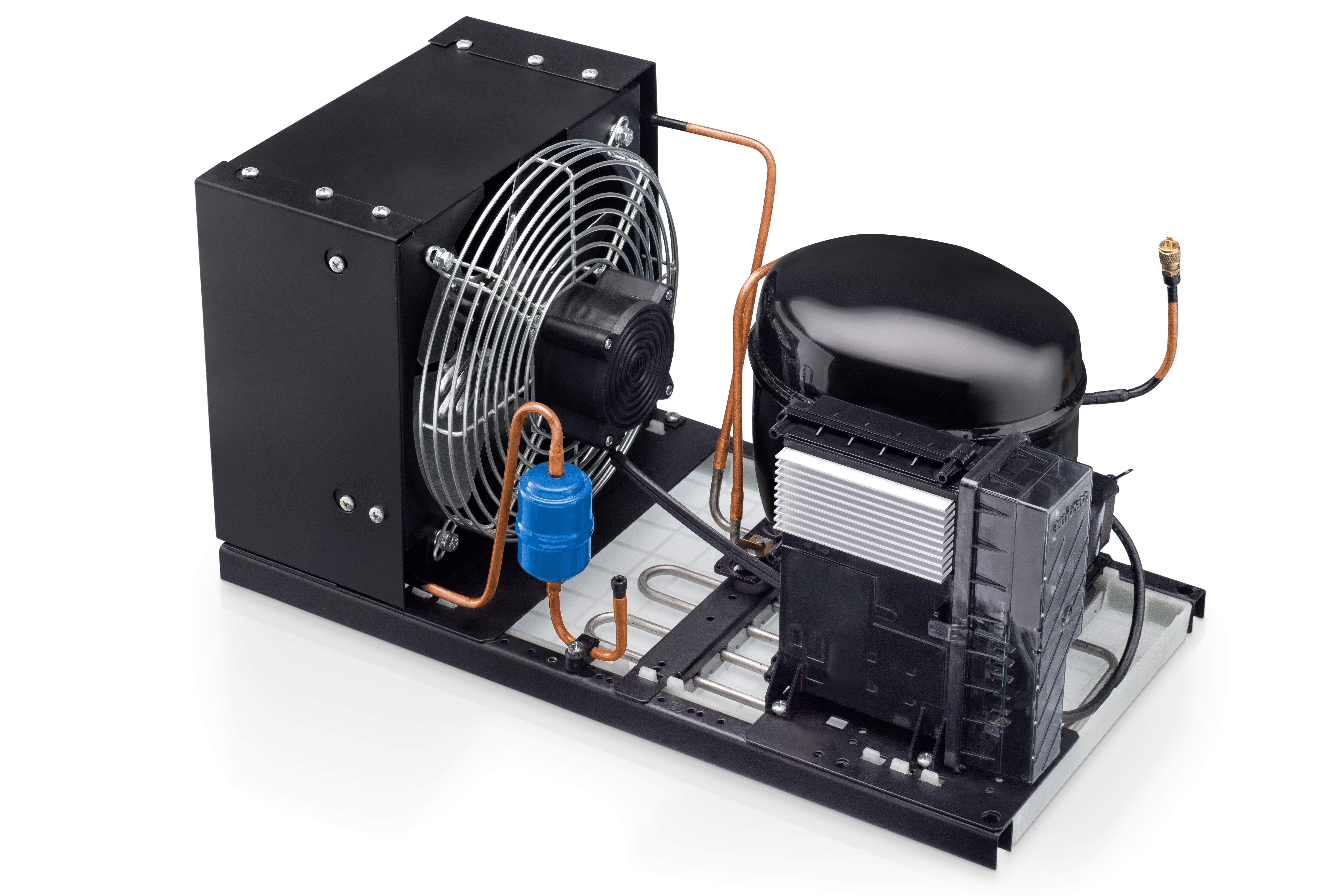

Condensing units: key components to facilitate customers’ lives

In this season of events in China, Embraco is also highlighting its portfolio of condensing units (CDUs) as a form of components’ integration to facilitate the customers’ lives. These solutions are key components in the refrigeration circuit, being composed of the compressor, condenser, fan and control elements, all integrated. They eliminate the effort of buying and assembling each system’s components from different suppliers.

As it did at Hotelex, Embraco will showcase at China Refrigeration and Chinashop its unhoused units and the Bioma series. The first are designed to suit a broad range of applications in food service and food retail, including coolers and freezers, with fixed and variable-speed compressor options. Bioma is a housed condensing unit for cold rooms with a robust design that absorbs vibration, wih models that range from 28 to 36 dB, making it the most silent in the market in this product category.

Compressors: local production and wide range of applications

Embraco is also presenting at the events in China a comprehensive lineup of compressors designed to serve a wide range of applications, with highlights to locally produced models.

NTX and NEX. The latest generations of Embraco’s renowned NT and NE product families, these fixed-speed R290 compressors are manufactured in China and developed for energy efficiency and robustness with low noise levels. NEX reaches up to 21cc of equivalent displacement and is suitable for ice makers, beverage coolers, and blast chillers. NTX, with up to 33cc of equivalent displacement, targets large applications such as island freezers and multideck reach-ins.

VEH and VEM. These two variable-speed R290 compressors are also produced in China, and deliver all the advantages of variable speed technology, such as high energy efficiency, improved temperature stability, low noise levels, and high tolerance to voltage fluctuations. The VEM is suitable for food service applications such as bottle coolers, professional kitchens refrigerators and freezers and under counters, while the VEH reaches a broader range of applications, from professional kitchen refrigerators and freezers to frozen islands and multi-decks, thanks to a cooling capacity range from 228 to 940W.

VNEX series. It is a variable-speed compressors line developed to serve large refrigeration equipment, such as reach-in commercial freezers with up to 5 doors, or vertical refrigerated display cabinets. With a maximum displacement of up to 21 cc, this series offers the highest cooling capacity and energy efficiency in this product category, with a maximum cooling capacity of 1670W and an efficiency of 1.86 W/W (tested in Ashrae LBP). It has been awarded the “Innovative Products” selection at the China Refrigeration Exhibition.

Embraco Atom. It is the smallest variable-speed compressor in the market for residential applications, launched at AWE trade show. Weighing just 2.5 kg and measuring less than 110 mm, it is 30% lighter than Embraco’s previously most compact compressor, the FMS. It was designed to be competitive enough to accelerate the migration from fixed-speed to variable-speed technology, being accessible to a wide range of refrigeration applications, from premium models to single-door refrigerators and beverage coolers.